NEW SOLUTIONS

IN THERMAL MANAGEMENT THROUGH ULTRAFAST LASER STRUCTURING

Quantum Qool is an innovative startup where its patented ultrafast laser surface structuring technology was developed by Chairman, Co-Founder & CTO Victor A. Rivas. The World Intellectual Property Organization approved all 13 claims of the technology in 2014 as being industrially applicable, novel, and inventive.

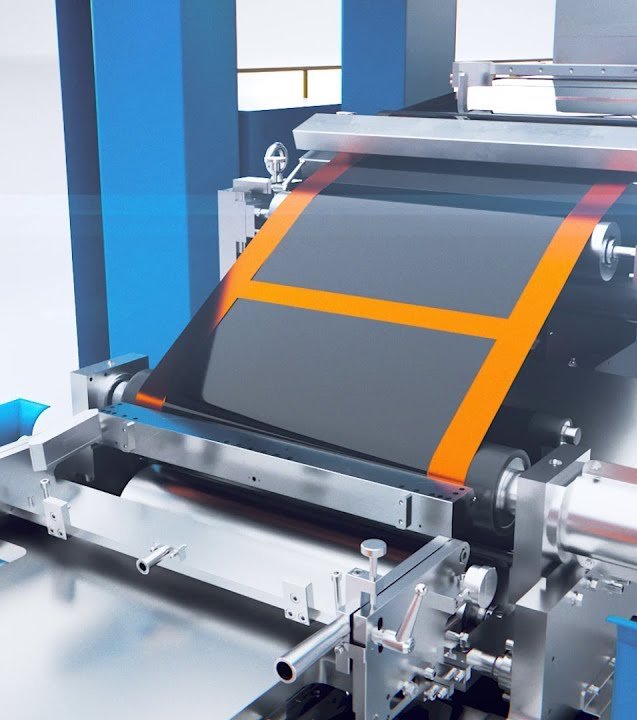

This laser functionalized surface tech is integrated into an ultrashort pulse laser multi-beam manufacturing unit, the Q2 Laser Station, to enhance the surface area volume/ratio of materials and their effectiveness in emitting thermal radiation (i.e. emissivity), which significantly improves power and heat management by factors of 10 times or more.

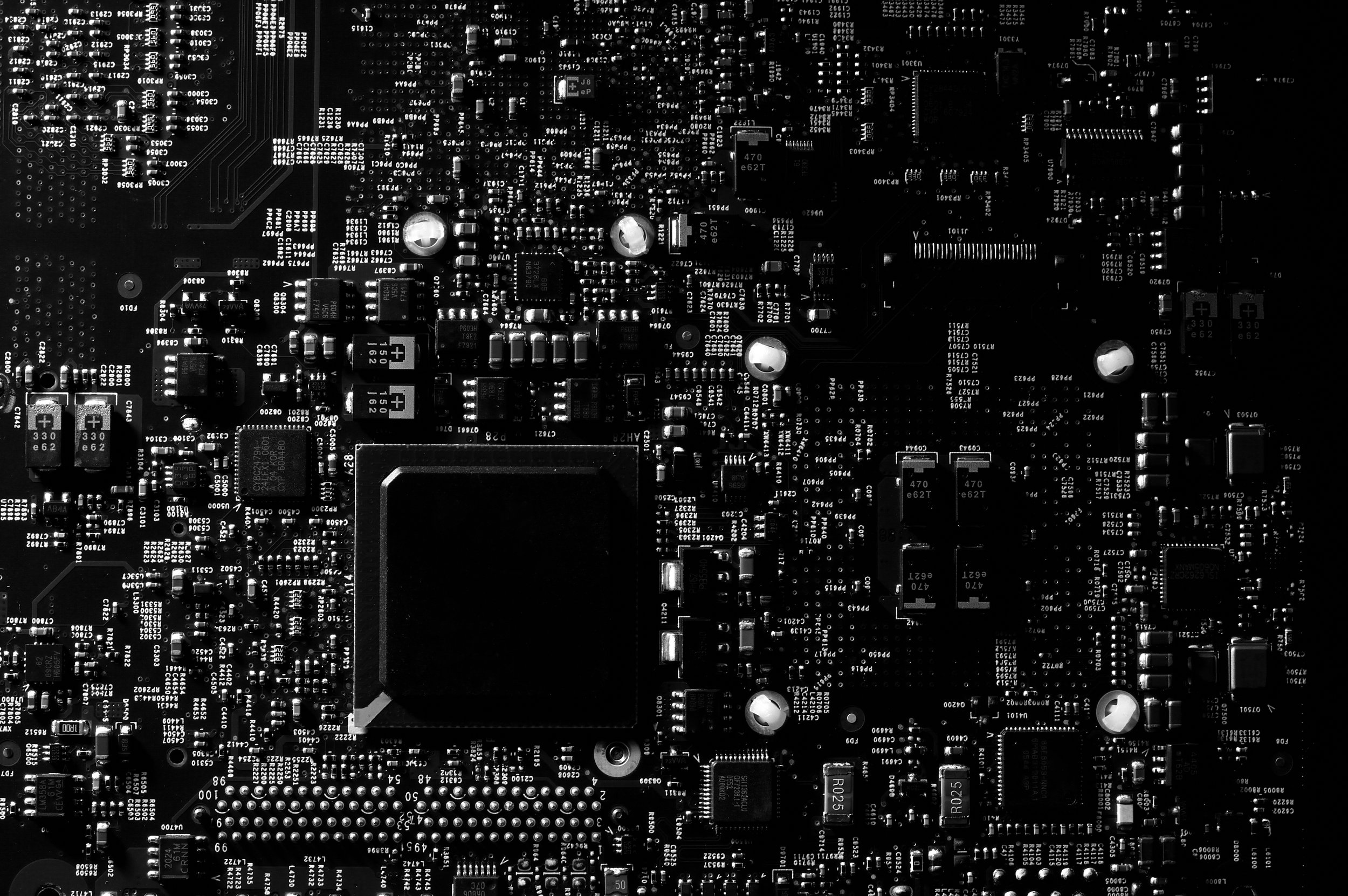

Fundamentally, the technology enhances the capabilities of materials & alloys such as copper, aluminum, nickel, graphite & silicon carbide with relevant micro- and nanostructures for multiple climate tech, defense and space applications.

The Q2 provides leading edge femtosecond laser performance with industrial reliability and integrated diffractive optics, which significantly boosts production throughput never seen before commercially. Ultrashort pulse “cold processing” lasers produce negligible residual heat effects and, thereby, prove ideal for precision processes that were, until recently, unachievable.

PATENTED ULTRAFAST LASER SURFACE STRUCTURING WITH CUSTOMIZED LASER STATIONS SCALED FOR PRODUCTION LINES.

TARGET MARKETS

-

SPACE COMPONENTS

-

HEAT SINKS & HEAT SPREADERS

-

BATTERY ELECTRODES

-

THIN FILM SOLAR CELLS

HOW IT WORKS

/

HOW IT WORKS /

OTHER LASER PROCESSES

When materials are laser machined, their electrons become excited and radiate the excess energy before coming back to a resting state. The time in-between can last anywhere from a few microseconds to a couple nanoseconds.

Using microsecond or nanosecond laser processing (long pulse) means broader intensity and more thermal diffusion. This leads to large, uneven valleys in the surface and the formation of heat-affected zones. Heat-affected zones typically lead to microcracks, which lend to substantial mechanical failures.

QUANTUM QOOL

Using our patented femtosecond (one quadrillionth of second) laser machining process, the pulse duration is so short that the excited electrons don’t have enough time to come back to a resting state before the processing is done, which leads to high penetration depth, less thermal diffusion, and faster fabrication speed for creating nanostructures for desired functionalities. This includes greater surface areas, more energy capacity and faster heat dissipation.

A DEEPER LOOK AT OUR RESULTS

A scanning electron microscope (SEM) image of this nickel material before & after displays the substantial increase in surface area & emissivity via nanostructures.

This can complement, augment and possibly eliminate conventional conduction & convection cooling methods involving fans or fluids, while increasing energy density.

Infrared imaging shows a brighter, machined microprocessor after ULSS, where its temperature is 10 degrees hotter, as it’s emitting more thermal radiation AWAY from the microprocessor.

This means optimized heat transfer, so the microprocessor can handle more heat at higher temperatures consistently, which keeps the device cooler overall.

Q2 Laser Stations For ULSS at Industrial Scale

-

Vaporize matter without generating heat on novel materials and products from metals, glass, ceramics, and complex compounds

-

Eliminate time consuming post processing steps, resulting in single step machining that delivers considerable technical and economic benefits

-

Eliminate chemical processes that create environmental problems during the machining process or as part of a waste stream

We can provide a customized thermal management solution for your components for both here on Earth and in space.